1MG FlippingBooks

Removing the guesswork from selective spraying

HARDI Australia has long been at the forefront of technological development for Australian farmers, giving way to a game-changing solution to the perennial agricultural problem of weed control.

Unlike traditional weed sprayers, which identify weeds using a boom with cameras attached, the Geoselect is a decoupled system that uses remotely-sensed data collected from a drone or fixed-wing aircraft to scan the area to be sprayed, allowing weeds to be identified down to the centimetre. The HARDI patented “per-pixel” processing algorithm can then tell farmers precisely how much chemical they will need before they start spraying.

“The system is able to calculate the percentage of weed infestation in each paddock to allow selective spraying,” says HARDI Business Development Manager Mark Armstrong.

“The difference between current prescription map versions and Geoselect is that GeoSelect uses much higher resolution cameras,” says Innovation Manager Heath Thompson.

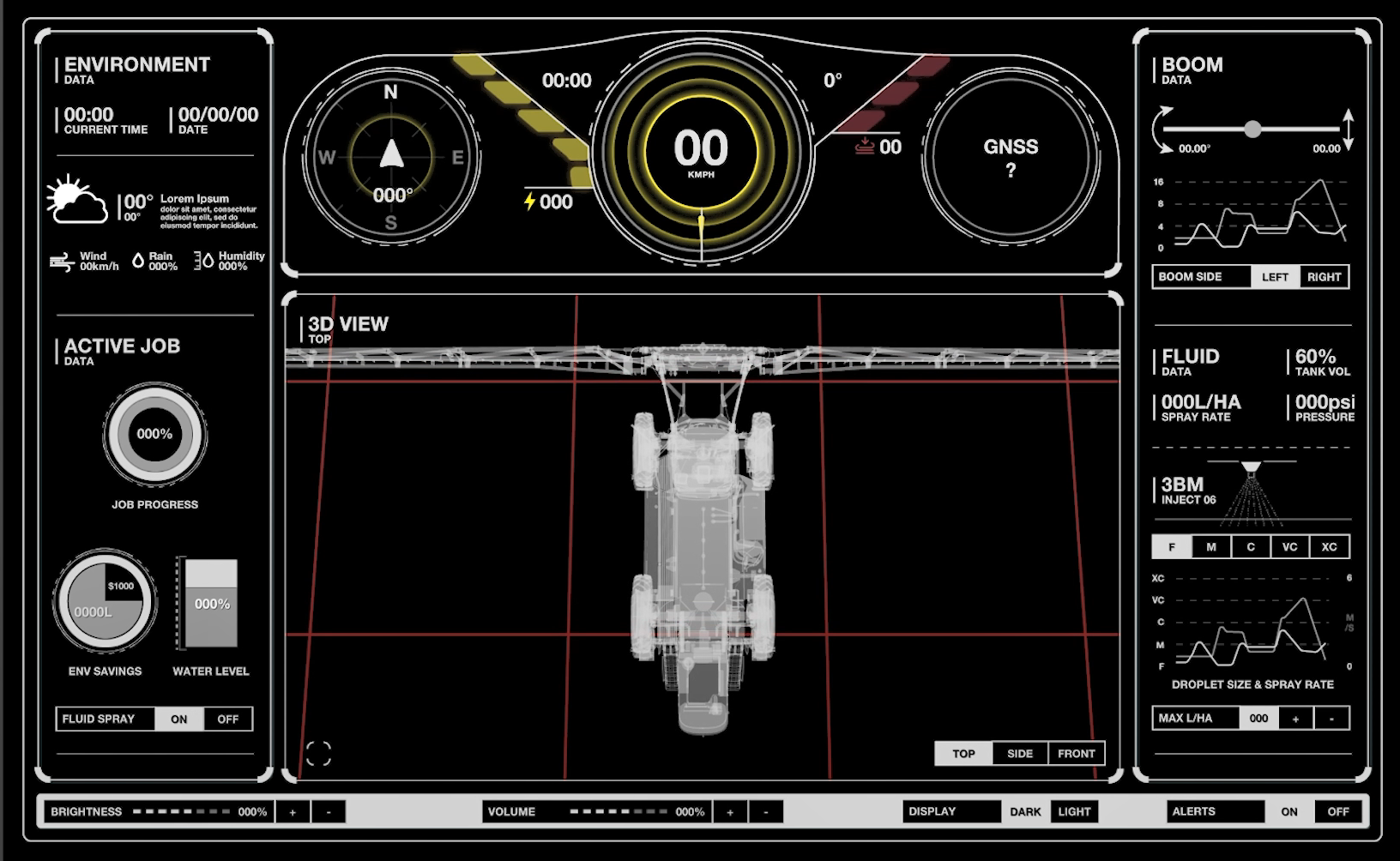

“We’re also using four GPS receivers on the boom that enables spraying at the same accuracy as the data captured by the drone. We’re spraying at a plant-based level rather than an area-based level, which is a big leap in capability.” Combining Geoselect with HARDI’s H-select system allows the system to know the positioning of the sprayer and each individual nozzle.

“Geoselect allows the farmer to save up to 90 percent of chemical per spray,” says Heath.

This, in turn, means fewer if any returns to the filling station. And because they don’t have to wait for reservoirs to refill, it allows farmers to increase their productivity. Saving time and product during the application process saves money, enabling farmers to invest in more expensive, higher quality chemicals that achieve better results.

The Geoselect system has already been successfully deployed on broadacre operations for summer fallow spraying, and HARDI plans to scale it down for future use in horticulture as well.

Heath says the system has been specifically designed for ease of use. “The map is firstly downloaded from the Cloud, then the drone operator tells the farmer how much chemical is needed for the job before they go out into the paddock and spray,” he adds.

And in terms of technical assistance, each machine is gateway-enabled, meaning HARDI technicians can dial in and see exactly what the farmer is doing in real-time.

The environmental benefits of reducing chemical use are immense – so much so that Heath describes it as a disruption to the agriculture industry. “It’s better for soil health because you’re not putting unnecessary product into the ground, and you’re also saving water. It’s also a great way for farmers to meet their corporate social responsibility requirements.”